Using Internal Controls to Keep a Record of Your Inventory: Costing Controls Best Practices

Jul 19, 2018

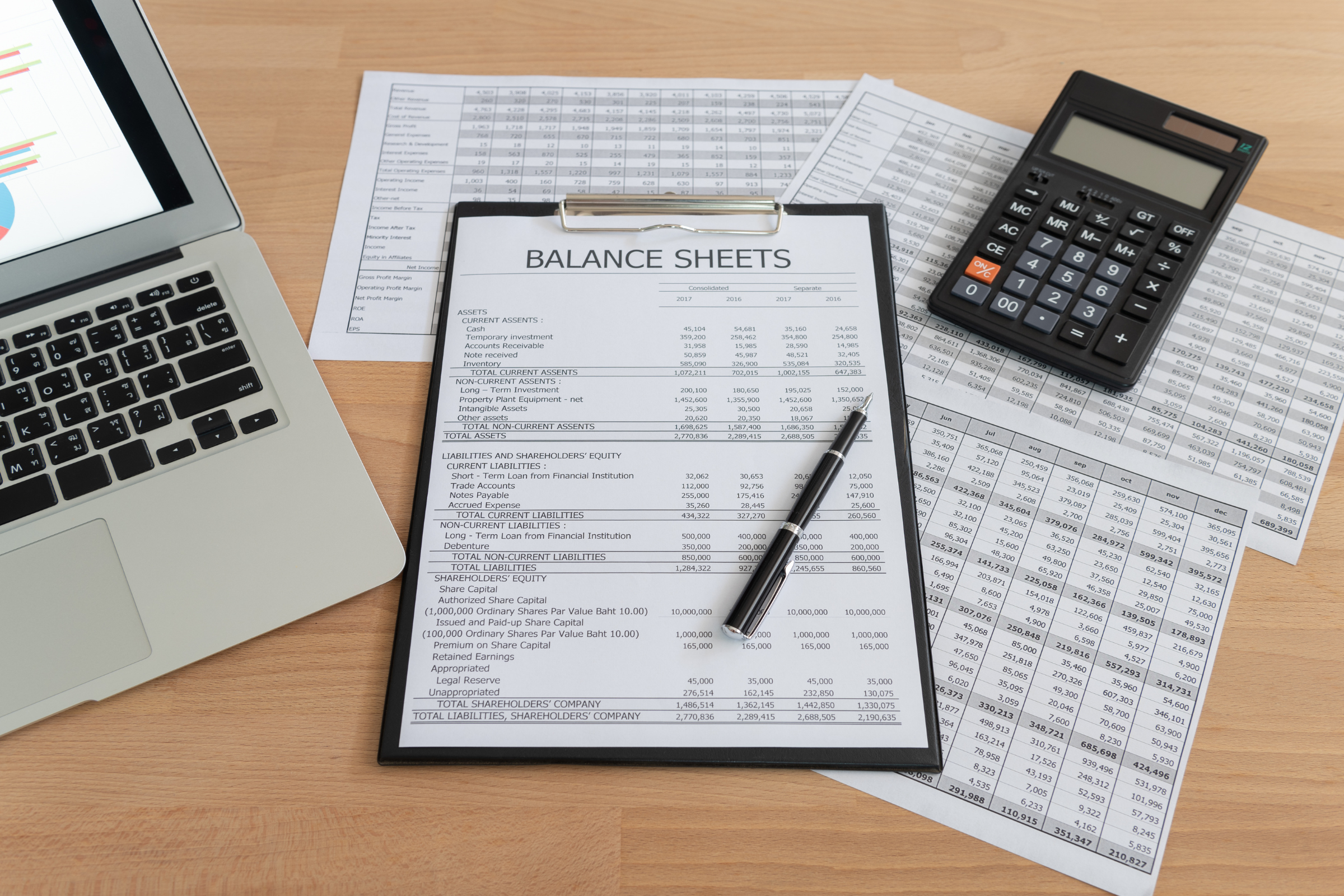

This article examines best practices related to inventory costing controls (i.e., the price component). It is equally important to track the accumulated costs associated with remastering inventory to a sellable condition and to know which products are overvalued due to damage, obsolescence, excess quantities, or any other cause.

Arranging Purchasing Controls

Internal physical and costing inventory controls should be based on a firm knowledge of what the company has purchased. Whether a business has raw materials for manufacturing or finished goods for resell, accurate costing begins when these items hit the floor. The following are internal controls that all entities should consider putting in place:

- Authorization procedures and policies for ordering goods, including approved purchase requisitions and purchase orders based on roles and management levels within the company.

- A process to match goods received against authorized purchase orders and to prepare a goods received report.

- Steps to match supplier invoice(s) to a goods received report and to authorized purchase orders.

- A reconciliation of the perpetual inventory listing to the general ledger.

Composing a Cost Accounting System

Cost accounting involves the methods by which a company determines the costs of products, processes, and projects to report the correct amounts in the financial statements, as well as make informed decisions regarding company operations. Most quality enterprise resource planning (ERP) software packages contain cost accounting functions. These functions effectively automate inventory costing and integrate it with the entity’s operations.

For a cost accounting system to achieve maximum effectiveness, it should be suited to a business’ needs. Therefore, a company should consider the following factors when determining how to best value and track its inventory.

Input Measurement Basis

Should a company apply only the actual costs of materials and labor to its inventory? Apply actual costs plus a predetermined factory overhead rate? Use standard costing? A standard costing system involves estimating the required costs of a production process. Before the beginning of the accounting period, a business typically estimates (or sets standards on) the cost of direct materials and labor required for a unit of production. The entity uses these estimates to budget for the production process and records standard-to-actual differences to variance accounts. Standard costing is a great monitoring and management control, particularly for manufacturing. For financial reporting purposes, a company should determine which variances should be expensed in cost of goods sold versus capitalized as of the balance sheet date.

Inventory Valuation Method

Depending on the industry, it may be appropriate (and more meaningful) for inventory costs to reflect only those of direct materials (e.g. retail and/or distribution) rather than all costs related to an inventory unit (e.g. manufacturing). When a business designs its controls, it is important that its valuation method aligns with its inventory objectives.

Cost Accumulation Method

Cost accumulation is the manner in which costs are identified, collected, and applied. Companies primarily use two methods. The first, job costing, compiles materials, labor, and overhead costs for an individual unit or job. This approach works well for unique products, such as custom-designed machines or consulting projects. The second is process costing, which compiles aggregate production process materials, labor, and overhead costs and then allocates them to individual production units. This type fits well with large production runs of identical items.

Cost Flow Assumption

Cost flow assumption refers to how costs are incurred through inventory accounts. Costs may not accumulate the same way in which work is processed. First in, first out (FIFO); weighted average; specific identification; and last in, first out (LIFO) are various inventory-tracking methods. Both the company’s industry and cost accumulation method impact this decision point.

Mixing Other Inventory Costing Control Considerations

Businesses should also account for the following when implementing internal inventory controls:

IT general controls

As with all IT applications, physical and system access to the cost accounting platform should be restricted to relevant job responsibilities. Similarly, establishing processes for system changes, software updates, and back-ups is essential.

Inventory analysis

Management should have a good working knowledge of the company’s inventory components and gross margins. Monthly analysis and monitoring of actual results related to these factors and other key performance indicators can be very beneficial. There should also be an analysis that determines whether inventory on hand is overvalued. Is it obsolete? Can the company sell it for more than it costs? Does the entity have more in stock than what will sell within a reasonable time frame? Processes for routinely asking these questions will assist in developing correct inventory valuation.

Contact CRI for assistance with arranging your internal inventory costing controls; we can help you produce inventory processes designed to make your company more efficient.