How MaaS Is Revolutionizing Manufacturing

- Contributor

- Tom Carmichael, Jr.

Feb 23, 2021

Consider this conundrum: You're a manufacturer of widgets, and you need to create a new type of widget to serve your customers. If you create a model for the new widget using traditional manufacturing methods, it will derail your current production schedule and involve time-consuming setup and teardown. If you choose to use 3D technology to create the model, you have to buy an expensive 3D printer, hire tech-savvy employees to run it, and when you're done creating the new widget, the printer will sit in the corner collecting dust and depreciating in value until you need to create another model. What do you do?

For an increasing number of companies, the answer is "neither." A new type of business, called MaaS (short for "manufacturing as a service"), gives company leaders another option for optimizing their production and innovation.

MaaS is facet of a business trend called XaaS, which stands for "anything as a service." The term XaaS was coined to recognize how advances in technology have allowed businesses to expand what they are able to provide as services to their clients. MaaS companies have revolutionized the manufacturing industry by allowing businesses to take advantage of specialized products and services that save them time and money.

How does MaaS work?

In our widget example, the manufacturer would reach out to a MaaS provider that specializes in 3D technology and outsource the new widget project to it. The MaaS company would create the model for the new widget at market cost while also preventing the widget company from spending extra time and resources on the project. Since the 3D company specializes in this type of work, it can have its machines running regularly and efficiently, keep up on their maintenance, and stay up to date on the latest in 3D technology.

MaaS companies offer a range of solutions for manufacturing clients. In addition to the 3D technology in the widget example, other types of MaaS include:

- Data analytics: Collecting data at key points in the production cycle to identify ways to make the process more efficient.

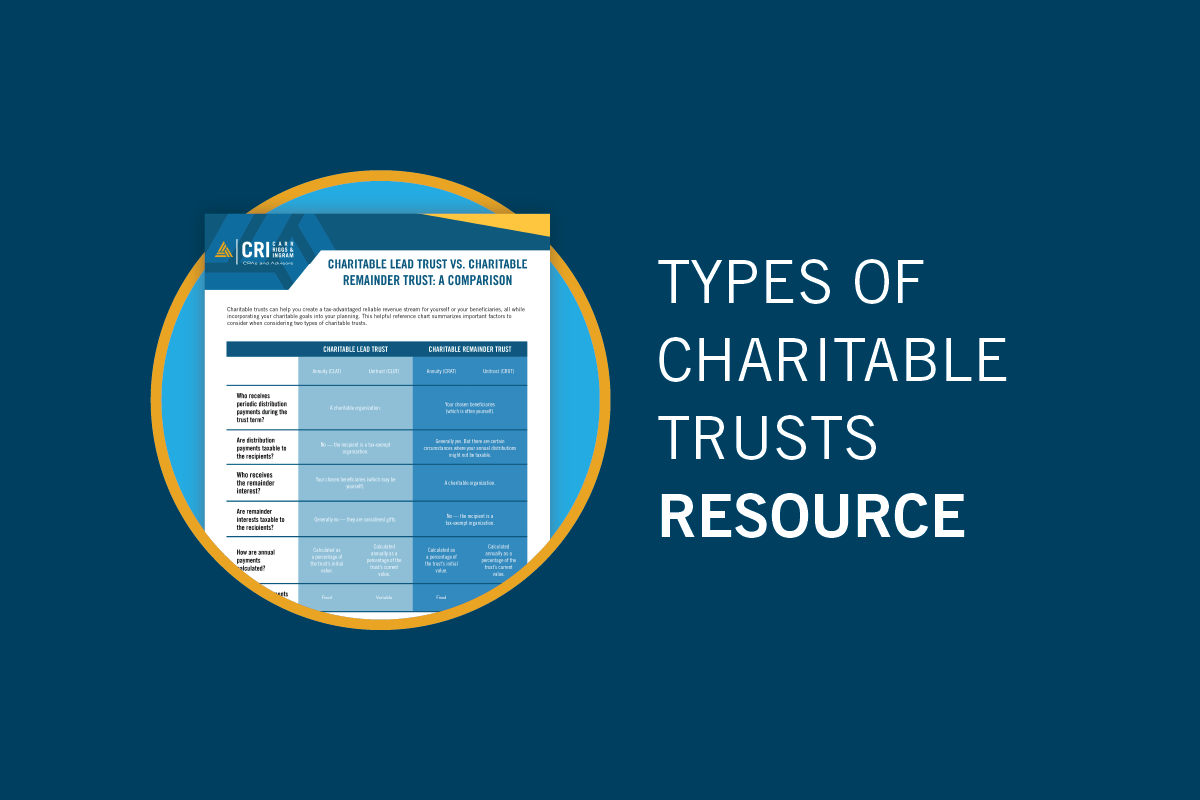

- Blockchain technology: Recording and maintaining records across a linked computer system to effectively manage transactions.

- Cloud computing: Hosting information on a network of remote servers in order to free up space on business computers and keep information safe.

- IoT ("Internet of Things") technology: Embedding sensors, software, or other technologies in objects that are part of the manufacturing process, which can gather and transmit information.

How can your company take advantage of the MaaS revolution in manufacturing?

Your company can seek out MaaS providers, become a provider itself, or do both. Ask yourself these four questions to help guide you through the new MaaS landscape:

- How would technology help make my company's manufacturing process easier, more efficient, more cost-effective, or more innovative?

- Is there a particular aspect of manufacturing that my company can specialize in, and how does technology figure into that specialization?

- How might IoT or data analytics help my clients?

- Can I implement technology to make client interactions and transactions more seamless?

CRI's professionals can help you work through these questions and determine how your organization can benefit from MaaS. Contact us today!