How to Manage Supplier Costs and Keep Your Business Balanced

May 9, 2018

Manufacturing and distribution companies often have to dance with suppliers. As raw material and transportation costs continue to climb, many distributors are encountering price increases from their suppliers. However, waiting for prices to stabilize is not an option for businesses feeling the squeeze of these increases. Therefore, consider the following strategies for managing supplier costs before finding a new supplier.

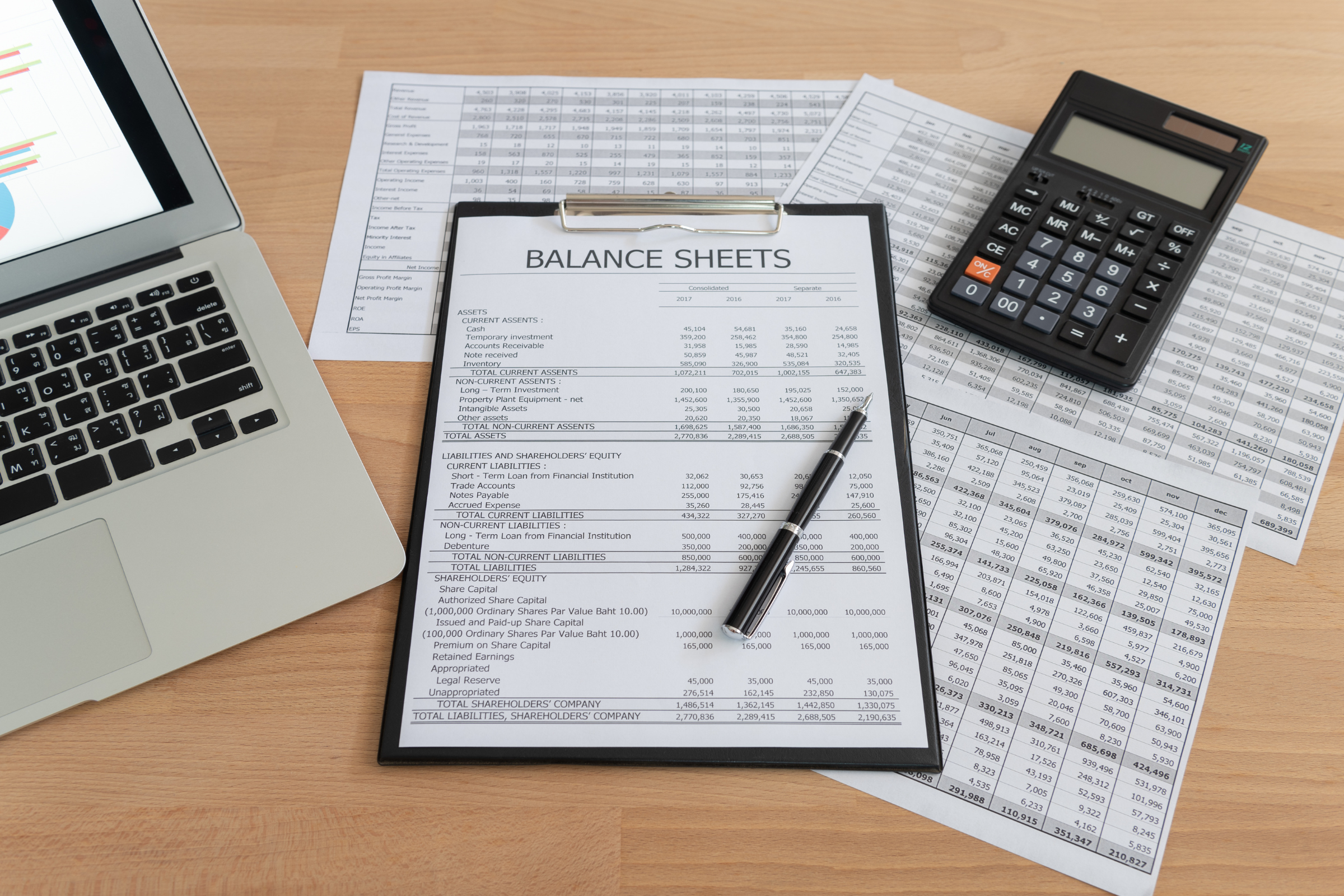

Record Your Steps

Recording how much each step of the manufacturing process costs is one way to understand where increased costs originate. Manufacturers should communicate with all involved in the process; the more information shared throughout the supply chain, the better.

If a company finds increased prices, it should work with the supplier to make changes to protect operations from spikes in supplier pricing or refrain from passing along the additional costs to consumers. If the supplier is unwilling to lower prices, the distributor should look for other ways to increase profits and cut costs to move around high supplier costs. Companies can also find lower costs by pre-purchasing or bulk purchasing raw materials. Buying in bulk often carries extra leverage with suppliers and can potentially give the company some control over the relative price of materials.

Using more energy-efficient equipment and production methods is another way to save on energy costs. Other resource-saving strategies include scheduling a regular night shift instead of employee overtime or subleasing the facility when it is not in use.

Finally, loyalty can prove valuable in relationships with suppliers, who usually make the final call on price increases. Manufacturers and distributors can keep suppliers happy by paying invoices on time and giving them ample lead time on orders. Building strong working relationships with suppliers can help foster compromises and reach fair prices – even during hard times.

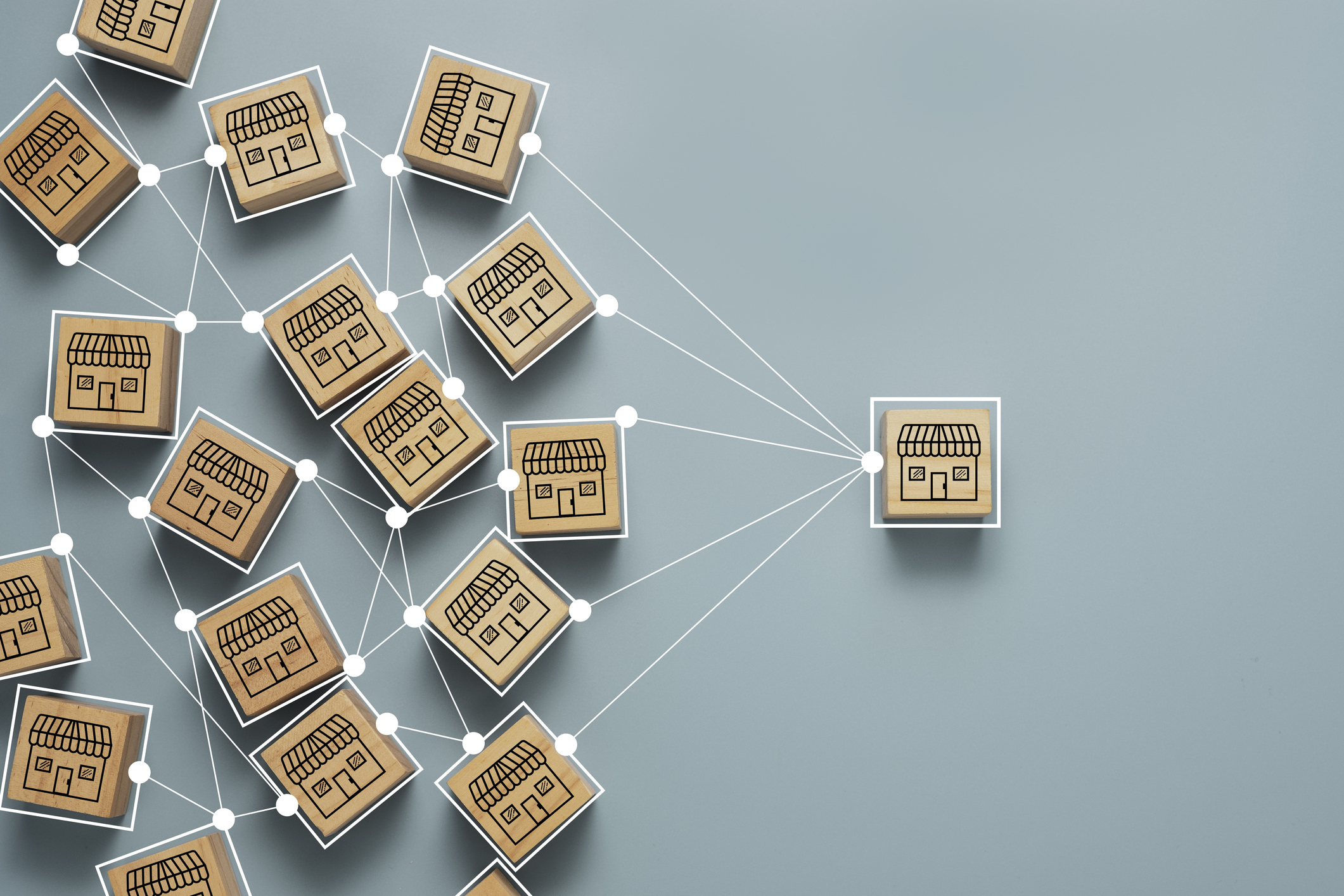

Finding New Partners for Your Supplies

When all else fails, forging ahead with a new supplier is the most fiscally responsible route. Choosing the wrong supplier, however, can cause more problems than it solves, so performing due diligence is key to finding a good match.

If a firm finds a new supplier, it should make sure that the supplier’s prices and payment terms allow it to meet revenue targets. Moreover, the supplier should be a reliable source long-term. In some cases, the firm may need to source raw materials from lower-priced economies. One consequence of choosing new suppliers is that they may disrupt the supply chain. Thus, the two teams must spend more time upfront to ensure a smooth transition.

Turning to New Suppliers

Rising supplier costs are a result of increasing raw material and shipping costs. To combat these cost increases, trim in-house costs, foster stronger supplier relationships, or (as a last resort) find a new supplier. CRI’s manufacturing and distribution CPAs can help determine the best course of action for your manufacturing and distribution company.